A StrategyDriven advisor supported the senior managers of a mid-sized regional utility in the evaluation of their work management program. This assessment identified opportunities to further align and streamline the many functional processes contributing to the identification, prioritization, planning, scheduling and execution of work. Collectively, these improvements enabled the managers to improve station equipment reliability and increase revenue generation while simultaneously reducing operations and maintenance costs.

Click here to gain access to StrategyDriven’s FREE Maintenance Inventory Optimization, Work Management-Supply Chain Interface Barriers whitepaper.

SituationFirst hand observation of a coal-based generation utility’s work management program revealed the following opportunities for improvement:

- Fleet average availability factor of approximately 80 percent compared with an 84 percent industry average

- The best performing plant had a preventive to corrective maintenance performance ratio of 1:3 instead of the 4:1 ratio typical of best performing industrial complexes

- Maintenance personnel frequently spent half of the work day idle; waiting for work start approval

Findings

A lack of work management, operations, maintenance, engineering, supply chain, and finance department coordination resulted in additional cost savings opportunities:

- Work planning and scheduling took place 3 weeks prior to work execution (T-3). Average component lead times were 4 weeks. The utility’s Supply Chain Director estimated that moving work order planning to T-6 would allow a reduction of $10 – $15 million in parts inventory (from the $56 million). Moving work order planning to T-12 was projected to result in a $25 – $27 million parts inventory reduction

- Operations Department work was not included in the station’s work schedule. Consequently, plant configuration activities needed to support planned maintenance were not performed until requested by maintenance personnel; often delaying work start by 4 hours

- Operations Department personnel prioritized work for each maintenance team after the work was assigned rather than collectively based on the station’s safety and reliability needs prior to distribution. Because some maintenance teams were assigned all low station-priority maintenance activities, these less important jobs were commonly performed while critical reliability-based repairs remained idle.

- No guidelines existed for prioritizing work resulting in the reprioritization of work by each operating crew and causing routine false work starts and stops for maintenance crews. These shiftly redirections significantly reduced overall Maintenance Department wrench time.

- Finance Department personnel determined outage duration based on estimated cost without input from Engineering Department personnel. Engineering Department personnel monitoring boiler tube integrity predicted that the outage duration assigned was not adequate to replace all failing boiler tubes and that a subsequent unplanned outage would occur during the peak summer months. This predicted outage did occur within 10 days of the engineering estimate at a significantly higher expense to the utility

- Work Management Department personnel routinely performed the work of engineering and supply chain staff at the expense of work planning and scheduling activities

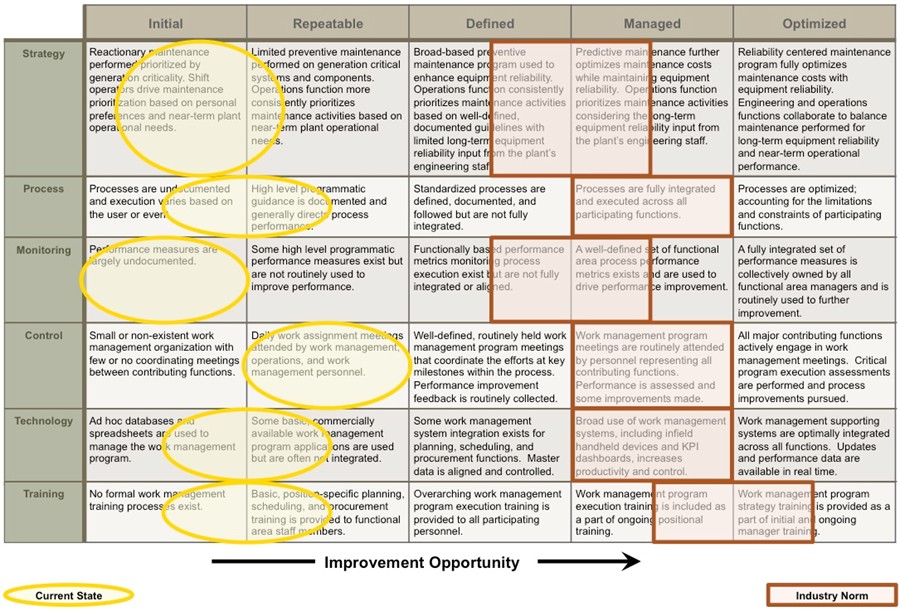

Figure 1: Work Management Program Maturity Model

Measurable, Attainable Benefit Targets

Optimization of the utility’s work management program was projected to drive significant revenue increases and cost savings including:

- 4 percent increase in total generation (if only industry average levels were achieved)

- $10 – $27 million in reduced component inventory + carrying costs

- Reduced maintenance costs (a preventive maintenance program is generally accepted as being 1/3 to 1/4 the cost of related corrective maintenance and enhances the functionality and extends the life of associated equipment)1

- Reduction in total outage – planned and forced – costs (while studies reveal that extending planned outages only yields an approximate 59 percent reduction in forced outage duration, the economic return of the much less expensive planned outages has been estimated at 77 percent in overall outage cost reductions)2

- Lower fuel per MWe generated costs

- Fewer greenhouse gas emissions per MWe generated3

Other Benefits

Other, non-operational financial benefits included:

- Deferral of new generation capital investments

Learn how StrategyDriven can help you optimize your work management program.

References

- “Life Based Maintenance Policy for Minimum Cost,” T. Chitra, IEEE, 2003

- “Performance of Generating Plant 2004 – Section 6: CASOM 18: The Relationship Between Scheduled Maintenance And Forced Outages And Its Economic Impact On Selecting Availability Goals,” Robert R. Richwine, World Energy Council

- Coal Online, “Coal combustion technology for a competitive power market,” IEA Clean Coal Centre 2006, p. 157.

Leave a Reply

Want to join the discussion?Feel free to contribute!