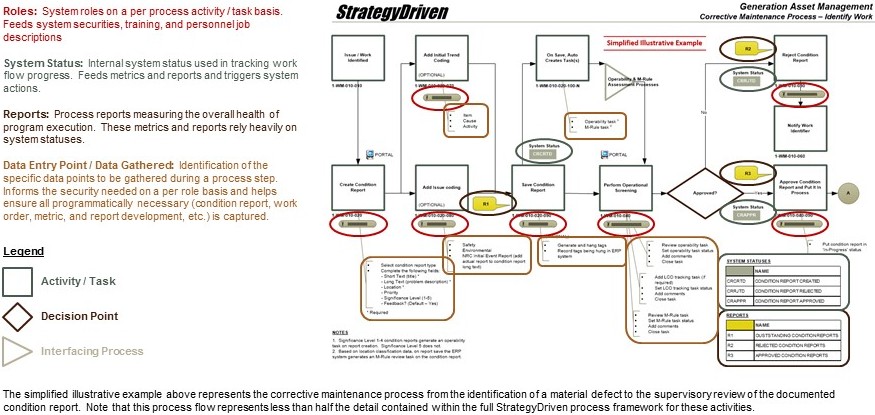

Critical Process Diagnostics

StrategyDriven’s Process Performance Analytics quantitatively diagnose process compliance, target common industry challenges, and identify resource and time-dependent execution constraints.

Process Performance Analytics provide organization leaders with information regarding the efficiency and effectiveness of day-to-day process execution. These analytics expose unnecessary and divergent activities, discontinuities in transaction and data flows and resource and time-dependent constraints; the elimination of which increases overall throughput and reduces costs.

StrategyDriven Process Flowcharts graphically present this information in a manner that enables rapid identification of unnecessary and divergent activities, transaction and data flow discontinuities, and performance measurement points critical to the determination of overall process efficiency and identification of constraints. Armed with this information, organization leaders focus their performance improvement efforts on those issues most impactful to overall performance.

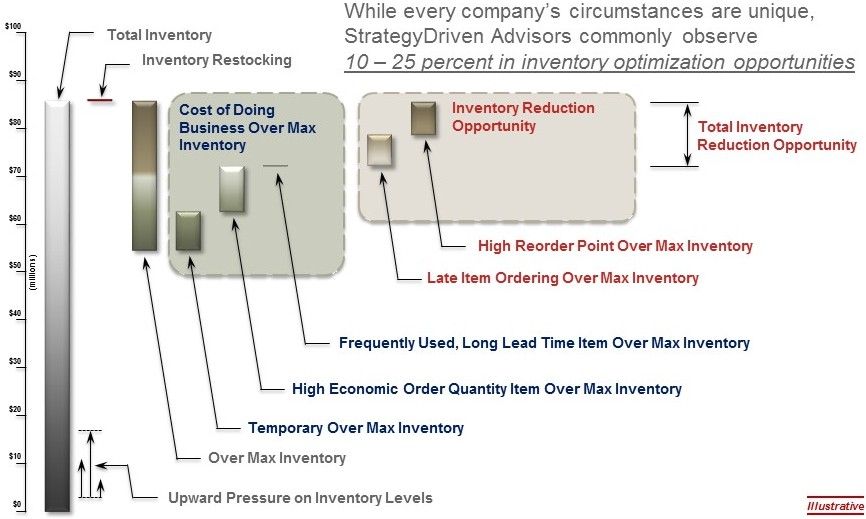

An optimized inventory is one that effectively balances the carrying, expediting, obsolescence, and expiration costs with ensuring items are available at the time of need. In short, optimized inventories minimize item cost while maximizing item availability.

Total Inventory: Aggregate cost of all items maintained in inventory

Inventory Restocking: Cost of acquiring items below their recommended reorder point (based on item use rate, lead time, and safety stock level)

Cost of Doing Business Over Max Inventory: Inventory levels over the management defined maximum resulting from normal business operations. These include:

Inventory Reduction Opportunities: Amount of over max inventory that can potentially be reduced over time through use, sale, or write-off (at such time that it becomes obsolete) including:

Note that Upward Pressure on Inventory Levels occurs because high item reorder points necessarily increase the minimum combined inventory level to be maintained.

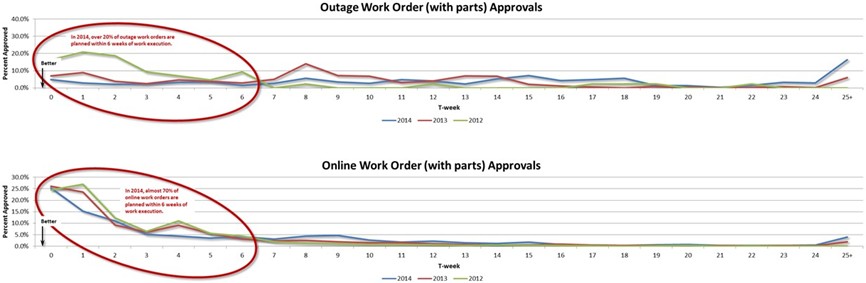

The work management process defines two of the key internal process parameters influencing inventory optimization. Work order approval establishes the specific items needed, their quantities, and represents when item demand originates. The scheduled work order execution date drives the timing associated with item availability.

StrategyDriven begins the work management process analysis with an evaluation of the process against our best practices model. We further evaluate process execution roles and responsibilities, integrations, and technology supports.

Timing Analysis

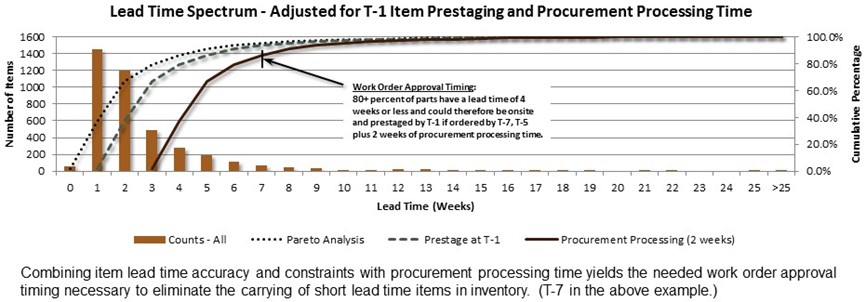

StrategyDriven assesses the work management process to determine the timing of work order approval (item ordering) and the several process inputs and parameters influencing this important milestone. Additionally, we evaluate work order execution schedule dates, their stability, and the several process parameters influencing this second milestone.

Quality Analysis

StrategyDriven then evaluates the accuracy of item ordering; whether the appropriate items were ordered in the necessary quantities. Further review of overall work order quality is performed if impacting schedule stability.

Collectively, analysis of these integrated process execution parameters yields the work management constraints and execution inefficiencies resulting in a suboptimized inventory.

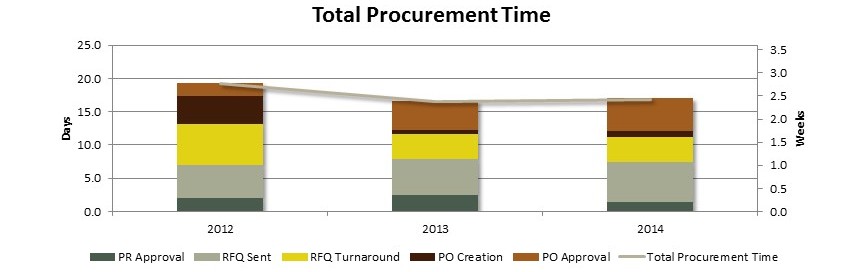

The procurement process resides at the heart of inventory optimization. Supply Chain personnel responsible for this process acquire the items demanded by the work management organization. This demand is satisfied by an issuance of a combination of ordered and stored items.

StrategyDriven begins the procurement process analysis with an evaluation of the process against our best practices model. We further evaluate process execution roles and responsibilities, integrations, and technology supports.

Timing Analysis

StrategyDriven assesses the procurement process to determine the amount of time required for purchase request, request for quote, purchase order, item receipt and issuance processing including the several process inputs and parameters influencing these activities.

Quality Analysis

StrategyDriven then evaluates item stocking logic, lead times and their accuracy. (See inventory characterization above.)

Collectively, analysis of these integrated process execution parameters yields the procurement process constraints and execution inefficiencies resulting in a suboptimized inventory.

The Inventory Optimization assessment concludes with a Work Management – Supply Chain interface evaluation of all process parameters, interfaces, and constraints from the start of work order planning through item issuance to identify those organizational, program, and technology barriers to smooth process transactions.

Inventory Optimization (Work Management – Supply Chain Coordination) Evaluation Report Assessments

Common Improvement and Optimization Findings

To obtain a complete list of the common inventory optimization barriers:

Download StrategyDriven's Maintenance Inventory Optimization whitepaper - It's FREE!

Focus of the Organizational Performance Measures Forum

Materials within the Organizational Performance Measures Forum focus on the principles, best practices, and warning flags associated with the leading practices of companies that successfully use performance measures to drive organizational alignment, accountability, and operational performance. StrategyDriven regularly publishes articles, podcasts, documents, and resources within the forum cover those topics critical to a strong performance measurement system.

Click here to visit the StrategyDriven Organizational Performance Measures Forum.