How You Can Best Use Modern Equipment to Optimize Your Manufacturing Efficiency and Productivity

One of the most effective ways to make your business more profitable is to work toward boosting its manufacturing efficiency and productivity. After all, if you can more efficiently produce the products you are selling, you will be able to turn a larger profit when you sell them.

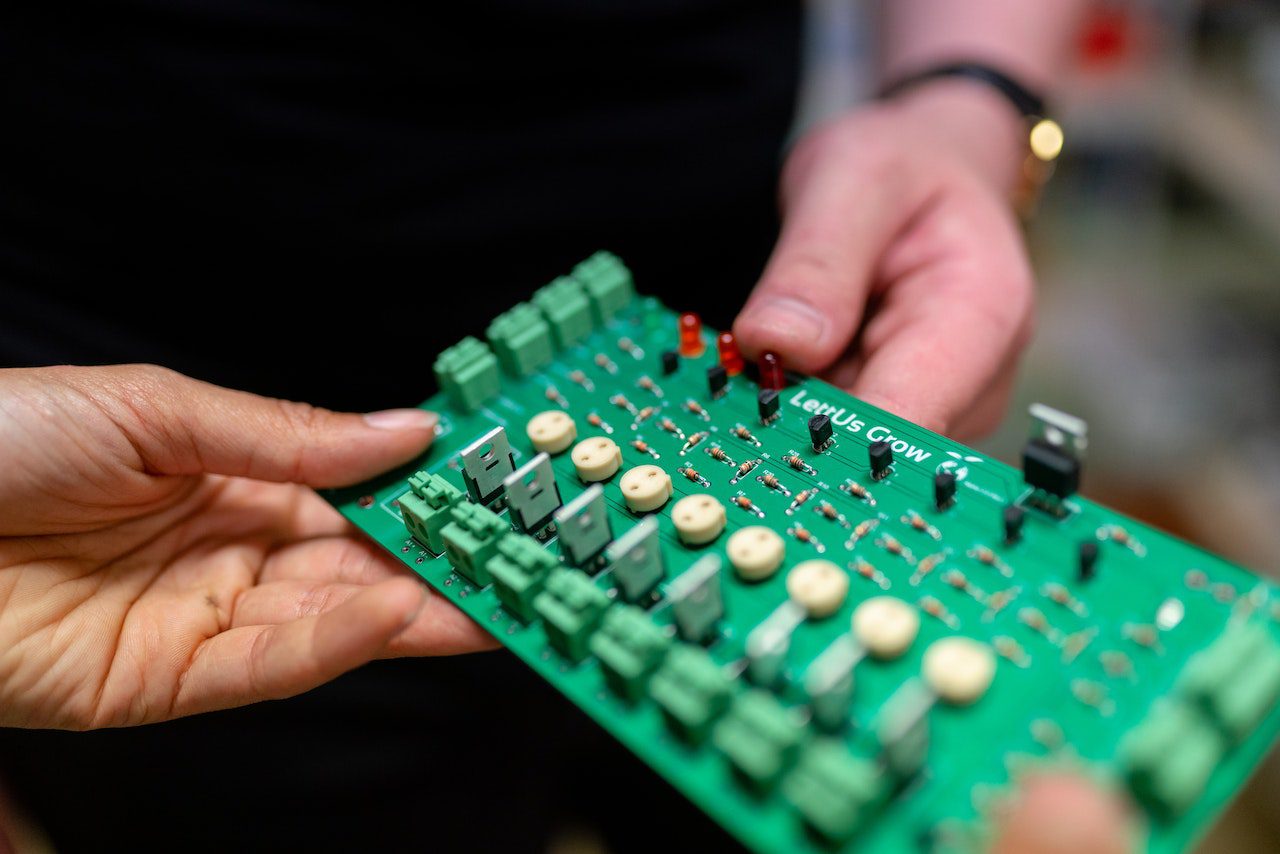

Fortunately, you happen to live in a golden age of technology, which means you could greatly boost your production speed and effectiveness by embracing the power of cutting-edge modern equipment.

Of course, using this equipment to optimize your manufacturing processes comes with risk, but any good business owner knows how to determine whether a risk is worth the potential for reward. With that in mind, this article aims to give you the information you need to decide for your own business.

Enhance Your Workforce’s Capabilities

Integrating contemporary technology into your business can be a massively effective way to enhance the scope and depth of your workforce’s capabilities. After all, a poor workman may blame their tools, but a foolish workman completely disregards the benefits that their tools provide.

By providing your workforce with a range of high-quality modern tools, you can enable those workers to work faster and to a higher standard than they would ever be able to without that technology.

Training With Tools

Of course, you will also have to ensure that your employees are able to effectively work with the tools you provide them, which means you will have to provide those workers with the necessary training.

For example, a dry screw vacuum pump can bring a lot of benefits to your business – particularly since it doesn’t require constant oil changes to operate. However, those benefits would be wasted if your employees aren’t knowledgeable about Dry Screw Vacuum Pump Working Principle.

As a result, proper worker training is another aspect of modern equipment upgrades that you will have to consider.

The Integration of Automation

Of course, you could completely evade this problem by simply investing in high-quality automation technology within your manufacturing process. This can help to give a massive boost to the productivity and speed of your manufacturing line without having to provide every single employee with the training to master a new skillset.

However, you will still have to provide certain employees with the training necessary to monitor and maintain the automation technology that you invest in.

What’s more, despite the benefits of integrating automation like this, you do also take on the additional risk of having a single – potentially devastating – point of failure within your manufacturing process. The tradeoff to that risk is a faster, cheaper, more reliable production process.

Smart-Maintenance and Monitoring

Finally, another benefit of contemporary technology lies in how easy it is – relatively speaking – to determine when and how these machines will need to be serviced and maintained. What’s more, many of the most advanced options in workplace tech require far less hands-on maintenance than their predecessors.

As a result, your company will be far more capable of predicting the maintenance needs of your equipment and planning around those needs to avoid potential interruptions to your manufacturing processes completely. After all, if you know in advance that you will need to spend an hour or longer performing maintenance on your machinery, you can plan to do that during the least disruptive times possible.