5 Ways to Increase Productivity at Your Manufacturing Facility

If you’re like most business owners, you’re always looking for ways to increase productivity. When your manufacturing facility is more productive, it means that you’re making more products and generating more revenue. This blog post will discuss ways that you can increase productivity at your manufacturing facility.

1. Review your manufacturing process

The first step to increasing productivity is to review your manufacturing process. You may be surprised to find that there are areas of your process that are inefficient or could be improved. By reviewing your process, you can identify these areas and make changes to improve them.

One way to review your process is to create a flow chart. This will help you visualize how each step in your process works and where there might be potential bottlenecks. You can also use this tool to identify which steps could be automated or made more efficient.

2. Safety first

Another way to increase productivity is to focus on safety. When your employees are safe, they can work more efficiently and with fewer injuries. This means that they’ll be able to work more hours and produce more products.

There are a few ways that you can improve safety at your manufacturing facility:

- Make sure that you have adequate lighting so that employees can see what they’re doing.

- Provide training on how to safely use equipment and handle materials.

- Make sure that there is a clear process for reporting accidents or incidents.

3. Invest in quality tools

Investing in quality tools is another way to increase productivity. When your employees have the right tools, they can work more quickly and efficiently. This means that they’ll be able to produce more products in a shorter amount of time.

An 80 lower drill press jig will save time and money in your manufacturing process. This is because it allows you to quickly and easily create perfect 80 lower receivers. With this jig, you’ll be able to produce more products in a shorter amount of time, which will increase your overall productivity.

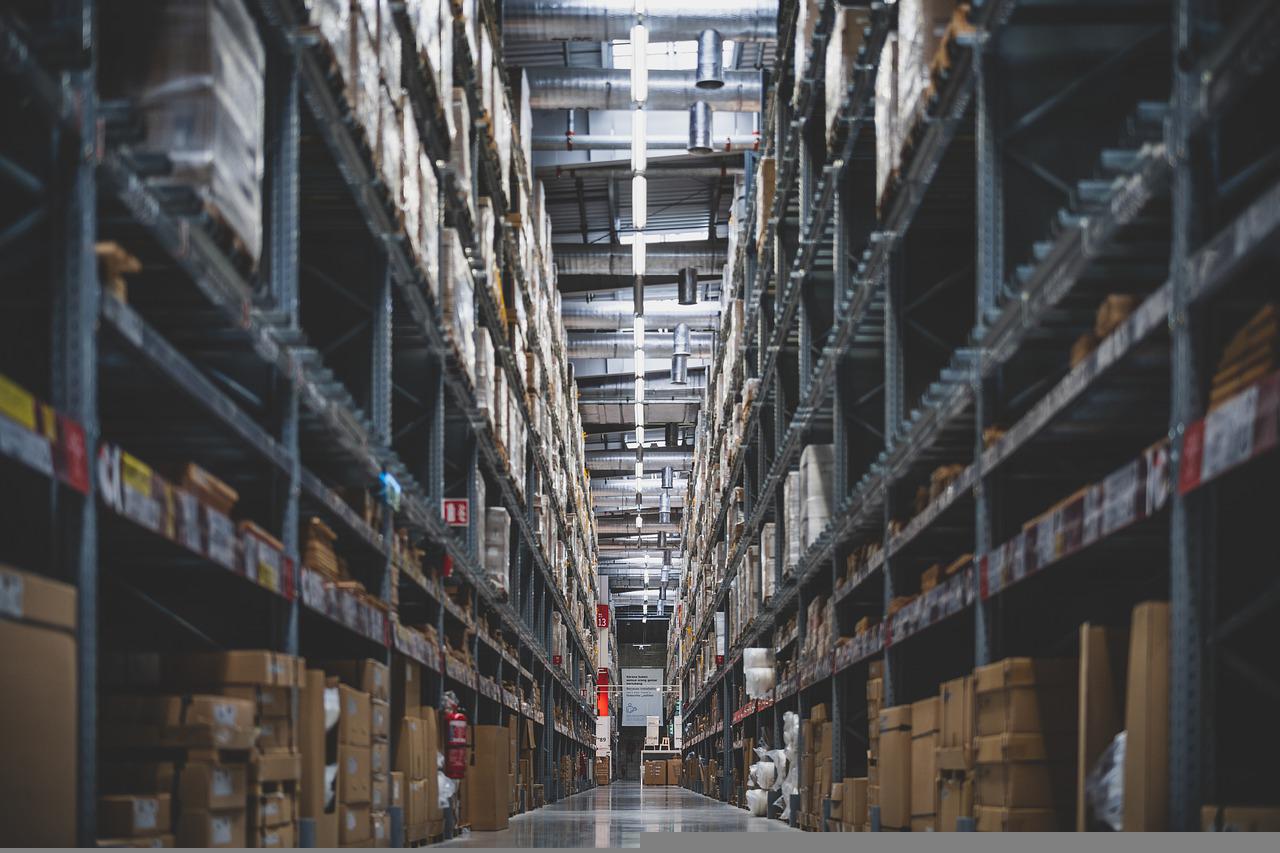

4. Take Inventory

One way to increase productivity is to take inventory. This may seem like a time-consuming task, but it’s actually quite simple. By taking inventory, you can ensure that you have the materials and supplies that you need on hand. This will save you time because you won’t have to order new supplies as often.

Inventory management software can help you keep track of your inventory levels. This software can also help you automate the ordering process so that you don’t have to do it manually.

5. Regular maintenance

Another way to increase productivity is to focus on regular maintenance. When your machinery is well-maintained, it will run more efficiently and with fewer problems. This means that your employees will be able to work more hours and produce more products.

There are a few things that you can do to ensure that your machinery is well-maintained:

- Make sure that you have a preventative maintenance plan in place. This plan should include regular inspections and servicing of your equipment.

- Make sure that you have the right replacement parts on hand so that you can quickly fix any problems that occur.

- Make sure that you document all maintenance activities so that you can track your progress over time.

By following these tips, you can increase productivity at your manufacturing facility. You can make your facility more efficient and productive by reviewing your process, investing in quality tools, taking inventory, and focusing on regular maintenance. Implementing these changes will help you increase profits and grow your business.