The Ultimate Guide on How to Boost Production Line Efficiency

As a production line manager, you strive to maximize the output without sacrificing quality. Unfortunately, this isn’t always possible. According to a report by Carpedia, most companies use up approximately 50% of their equipment and labor resources.

Tips on How to Improve Production Efficiency

Understanding what you’re making

While it may seem odd that anyone would manage a production line without knowing their product, the fact is that managing a production line doesn’t necessitate fully understanding the final product inside out. However, this doesn’t mean that you shouldn’t take some time to know the product and the production process intimately. When you know what the final product is supposed to achieve, you may be able to identify some parts of the production process that you can alter. For instance, you may find it cheaper to outsource your PCB Assembly tasks.

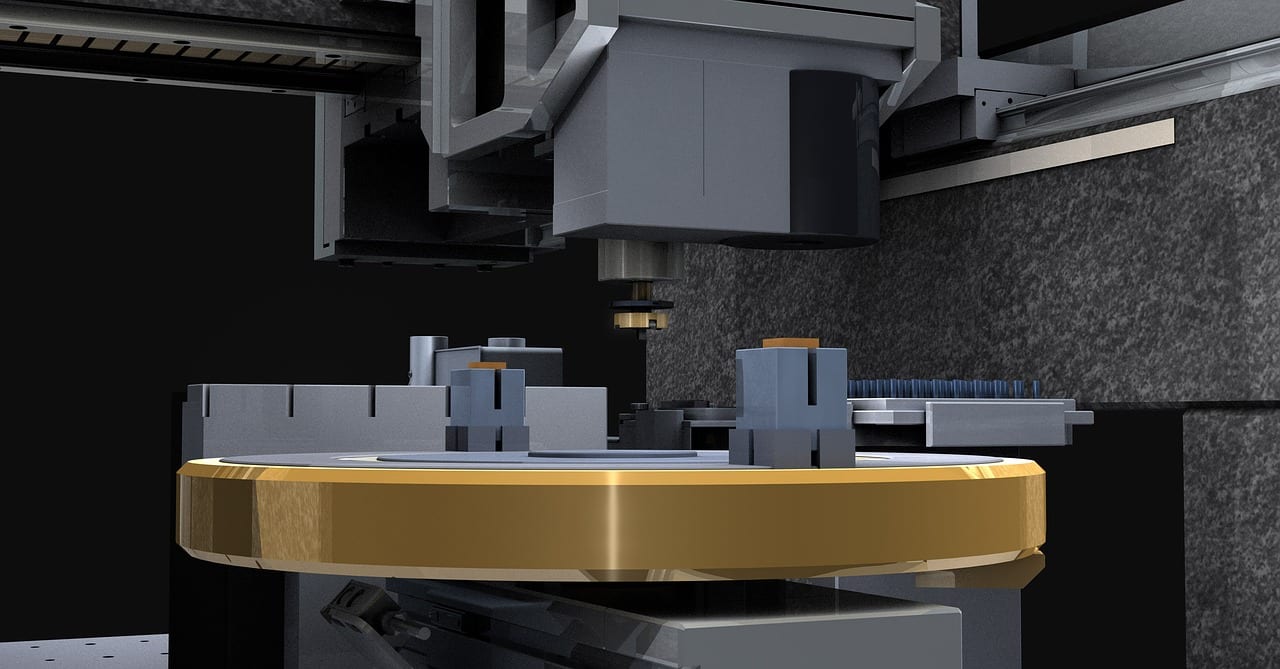

Effective automation

Replacing your employees with a machine isn’t the wisest choice. For production to be efficient, automation should be effective. As a production line manager, you want a return on investment. Therefore, you should make sure that any machine you invest in doesn’t need constant maintenance or supervision. This will help free up your staff so that they can perform more valuable work that cannot be done by a machine.

Improve on safety

There are several safety risks in factories that use production lines. Therefore, you have to consider the use of heavy equipment and machinery, and the handling of dangerous materials, especially if they’re hazardous. If your employees often deal with electrical items, there could also be a fire risk. As the person in charge, you can make your workplace more efficient by improving your employee safety.

Schedule preventive maintenance

A little maintenance of your production line equipment will go a long way in warding off bigger problems later. Most companies schedule regular checkups for their equipment. However, scheduling maintenance reminders can help your employees to remember when checkups are due.

Train your employees

Employees are the lifeblood of your business, and if you find them inefficient, it may not be their fault. You have to train new employees to adhere to company standards, and when you don’t train them, they will copy those around them, which can lead to errors. You can standardize operating procedures after identifying gaps in your employee skills, knowledge, and processes. Ideally, you should do this before you create a training program.

Bottom Line

Boosting efficiency in your production line is an ongoing process. Therefore, don’t underestimate the value of taking time to understand your product, automation, safety to reduce workplace injuries, and equipment maintenance. Sometimes, it is the small strategic changes that yield the best results.

However, before you make any changes remember to always ask yourself the cost of that solution. . For instance, you can improve production line efficiency by investing in a new multimillion-dollar piece of machinery, but can you solve the problem with a cheaper alternative? Don’t use your business capital unless you have to.

Leave a Reply

Want to join the discussion?Feel free to contribute!