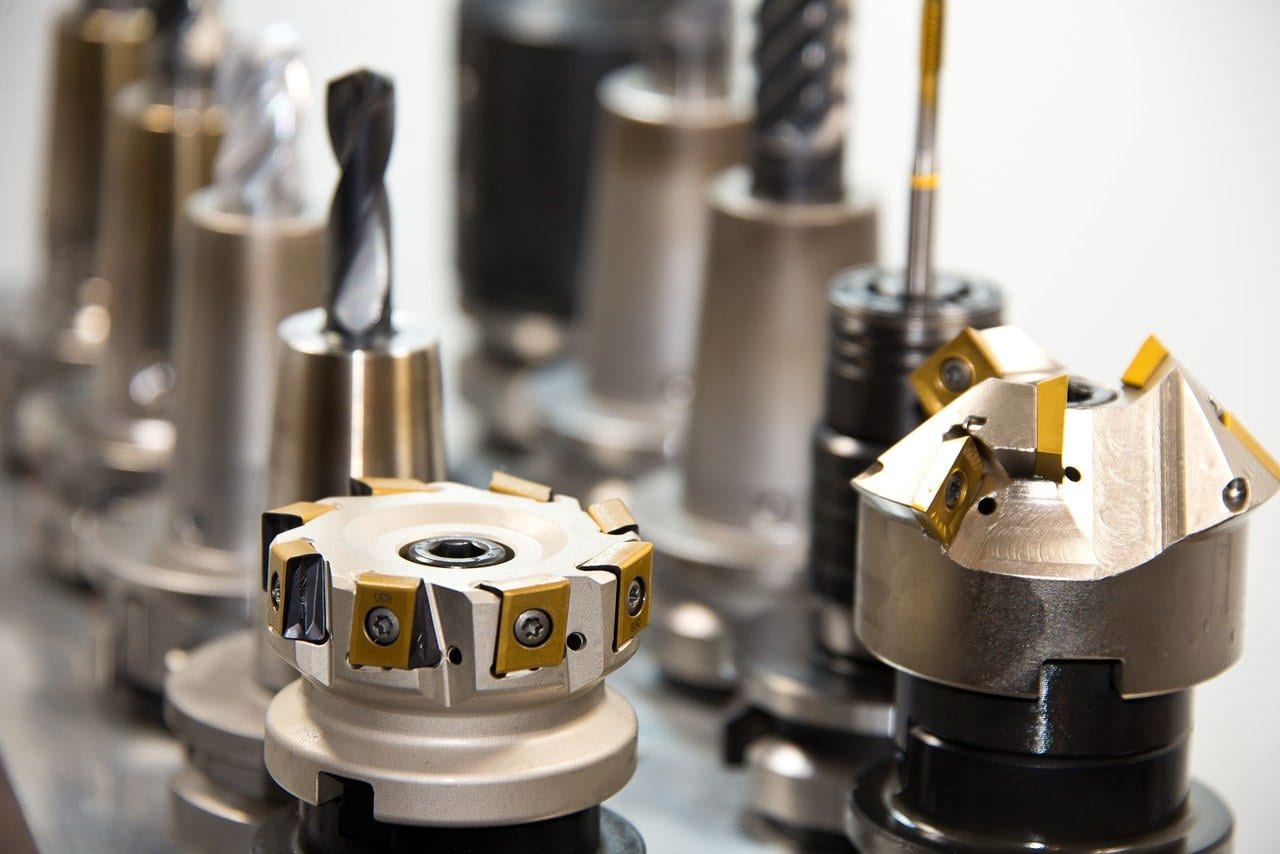

Strange Ticks Can Be a Sign of Trouble: 3 Things That Can Lead to CNC Machine Failures

When it comes to Heavy Duty Machining knowing what can go wrong is half the battle. Keep reading to learn about some of the most common issues that may occur.

1. Causes of Burning on the Exterior Edge of the Material

The good news is that while this issue is common, it is also a problem that is relatively easy to fix. Usually, the issue is the result of a feed speed that is too low or a blunt tool. The first thing to check is to see if the feed speed is right for the material that is being cut. Take time to look at the tool being used, too. Sometimes, all a person has to do is to replace a dull tool with one that is sharper or increase the feed speed if this issue is seen. Keep this in mind to deal with this common issue.

2. Making the Same Mistake More Than Once

The process of CNC machining is something that can take a lifetime to fully understand and learn. There is no point when someone can consider themselves to be a “master” who knows all there is to know about the process. There are new situations that will pop up all the time that require adaptation and new thinking -; even by people who have been using these machines for years or even decades.

This means that someone who wants to use a CNC machine should commit to always learning and taking advantage of new technology and new techniques. If a mistake occurs, see what can be done to change it so that it will not happen again.

3. Chatter

If the CNC machine begins to chatter, it means that it is vibrating while it is working. Chatter is going to occur to the entire machine or just to the tools that are being used. If chatter occurs, then it is going to harm the quality of the work, it will dramatically reduce the tool’s life, and can shorten the CNC machine’s life.

If someone wants to prevent chatter issues from occurring, be sure that the cut depth or width keeps the deflection under 1/1000th of an inch. The majority of CNC machinists will also react as someone slows down with the work that is being done. While this is not always a bad thing, there will be a better solution. Speeding up the work that is being done will also work -; so all a person has to do is to test various RPMs, to begin with.

Dealing with CNC Machining Issues

When it comes to CNC machining there are a lot of things to know. By knowing the various issues that can occur, it is possible to avoid them. Being informed and knowing what to expect when using a CNC machine is essential to make sure that accurate results are achieved.

Leave a Reply

Want to join the discussion?Feel free to contribute!